ASA case study for the CUOA Master in Lean Management

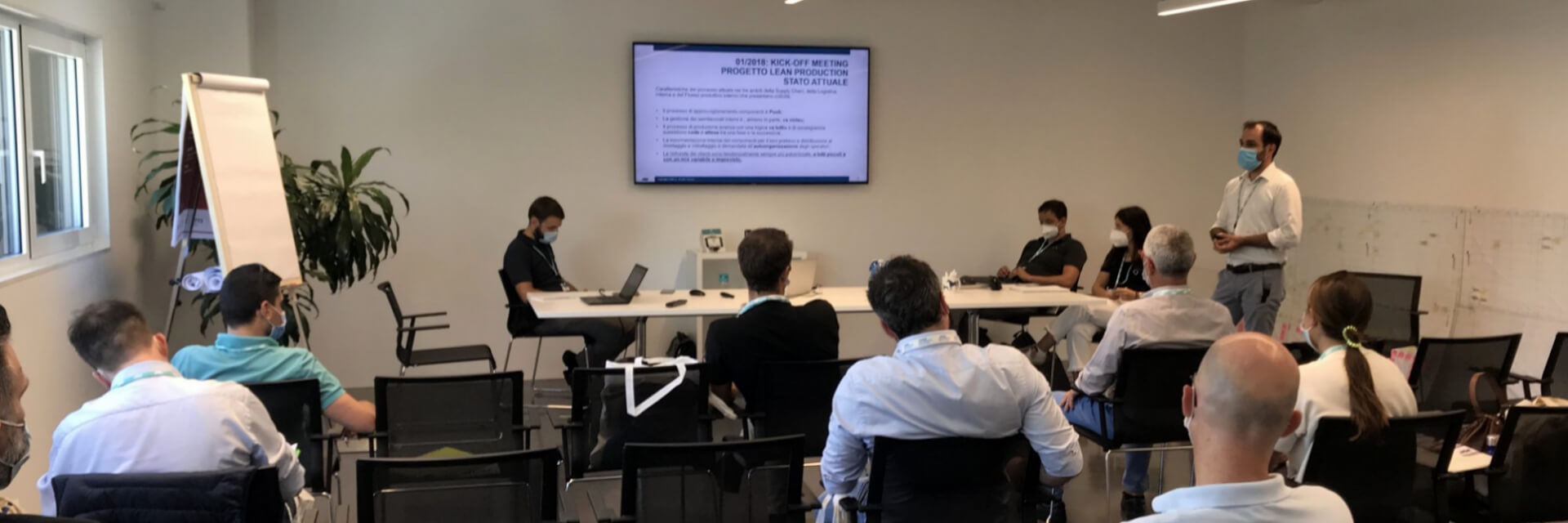

The "ASA Lean" project, carried out by implementing a One Piece Flow system for the assembly and testing phases of medical devices for laser therapy in the human and veterinary field, was the focus of one of the lessons of the sixteenth edition of the Master in Lean Management organised by CUOA Business School.

The training course, divided into theoretical lessons and Lean Application experiences in real gembas, shortens the distance between participants and companies and generates a virtuous circle of discussion on key issues such as processes, people, techniques and strategy.

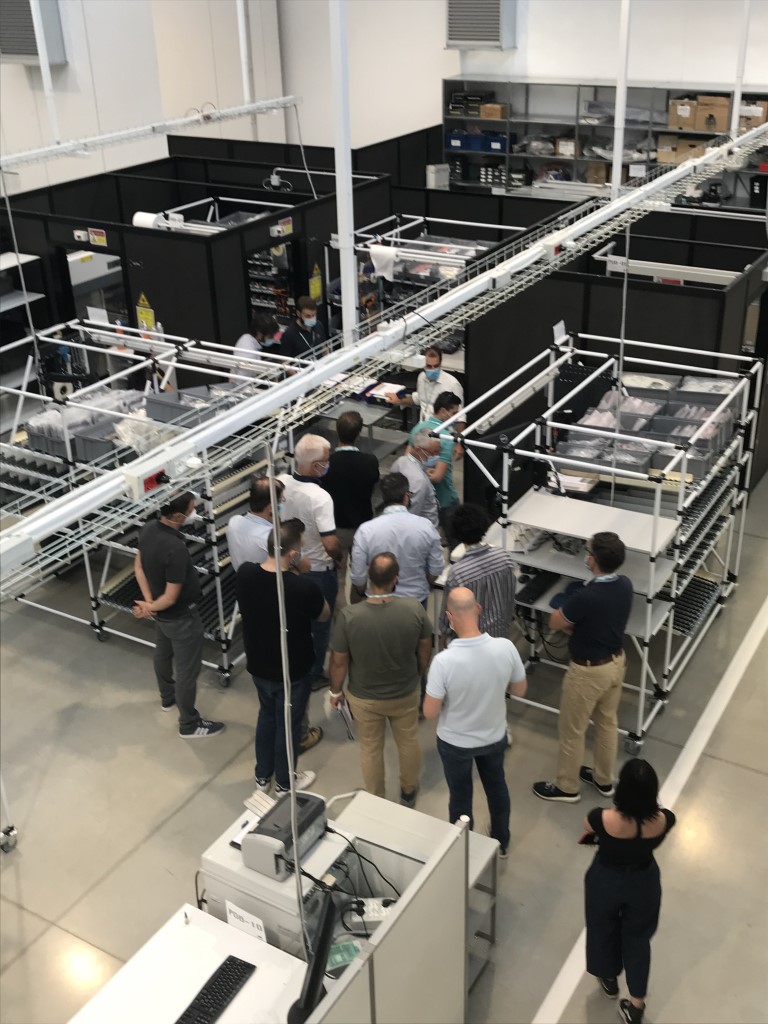

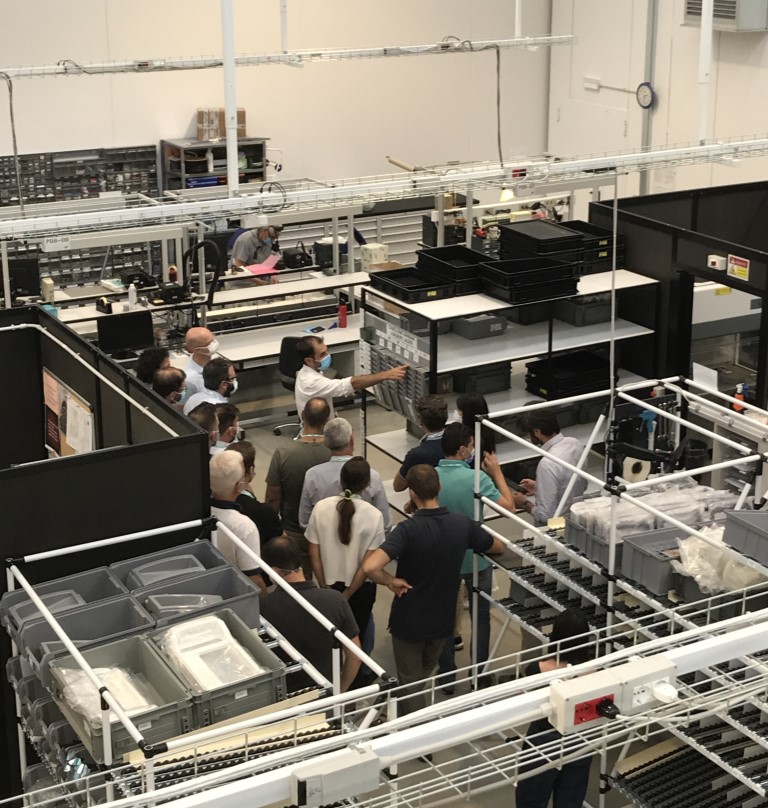

"Hosting the participants of the 2021 edition of the CUOA Master, whose Lean Centre has been considered the national reference centre on Lean Management issues for 15 years, is a source of pride for us. The lesson, held by the consultants from Sintesia, our Lean Partner, retraced the steps of the project that has seen us at the forefront from 2018 to today. The students were thus able to concretely understand concepts such as Visual Stream Mapping, 7 Muda, 5 Why, Kanban, One Piece Flow and Milk Run, also experiencing their application first hand”, explains Bruno Gastaldon, ASA Production Manager.

“Concretely verifying the fundamental steps of a Lean transformation of production processes and experiencing its positive impact on people's daily work - explains Andrea Cometti, Senior Consultant Sintesia – is an important phase to internalise the theory studied in the classroom and a stimulus to become protagonists of change, identifying with those who share the same experiences, difficulties and objectives”.

Roberto Marchesini, General Manager ASA, is also of the same opinion, recalling how the transformation process in a Lean perspective that concerns the company can represent a useful example for all those professionals, managers and entrepreneurs who lead or wish to start a process of Lean Transformation.

“Committing to this mode of production, minimising wastefulness with the final aim of eliminating it – he specifies – implies a progressive revision of one's working culture. A process that, although not simple, seeks to make us increasingly ecffective on markets around the world, aiming for conscious development”.

The further step taken by ASA, consisting of a Lean Office path that currently involves the Quality and Engineering departments, goes in this direction.

"Meeting with the students of the Master - says Alessandro Massignan, ICT department of ASA - was very useful because it allowed us to collect various ideas to reflect on”.